其他品牌 品牌

代理商厂商性质

国外所在地

BioFlex双向拉应力培养板, Uniflex单向拉应力培养板 、TissueTrain三维细胞组织培养板等系列细胞培养一起使用,

培养板类型、包被表面材料丰富:Amino, Collagen (Type I or IV), Elastin, ProNectin (R GD), Laminin (YIGSR).表面涂层丰富的

包被材料, 您可以跟根据不同细胞组织可以灵活选择不同包被材料表面 (包被材料选择参考)。

| 该应力加载系统配套培养板 | zui大伸展率 |

| Culture Plate for tension system | Max Achievable Strain |

| BioFLEX®双向应力细胞培养板(BioFLEX®CULTURE PLATES) | 21.80% |

| Tissue Train三维细胞组织培养板(Tissue Train culture plates) | 20.80% |

| UniFlex™单向应力细胞培养板(UniFlex™Culture Plates) | 12.20% |

| 24孔高通量BIOFLEX®培养板培养板(HT BIOFLEX®CULTURE PLATES) | 15.00% |

| No Loading Stations | 33% |

1、BioFLEX®双向应力细胞培养板(BioFLEX®CULTURE PLATES)

| BIOFLEX®CULTURE PLATES(BIOFLEX®培养板培养板) | ||

编号产品 | 产品名称 | |

| BF-3001U-Case(每箱40块) | BF-3001E-Each(每块) | BioFlex Culture Plate-Untreated(6孔表面未处理的BioFLEX®双向应力细胞培养板) |

| BF-3001A-Case(每箱40块) | BF-3001A-Each(每块) | BioFlex Culture Plate-Amino (6孔氨基BioFLEX®双向应力细胞培养板) |

| BF-3001C-Case(每箱40块) | BF-3001C-Each(每块) | BioFlex Culture Plate-Collagen Type I (6孔胶原I 型BioFLEX®双向应力细胞培养板) |

| BF-3001C(IV)-Case(每箱40块) | BF-3001C(IV)-Each(每块) | BioFlex Culture Plate-Collagen Type IV (6孔胶原IV型BioFLEX®双向应力细胞培养板) |

| BF-3001E-Case(每箱40块) | BF-3001E-Each(每块) | BioFlex Culture Plate-Elastin (6孔弹力BioFLEX®双向应力细胞培养板) |

| BF-3001P-Case(每箱40块) | BF-3001P-Each(每块) | BioFlex Culture Plate-ProNectin (6孔 ProNectin BioFLEX®双向应力细胞培养板) |

| BF-3001L-Case(每箱40块) | BF-3001L-Each(每块) | BioFlex Culture Plate-Laminin (6孔层粘连蛋白BioFLEX®双向应力细胞培养板) |

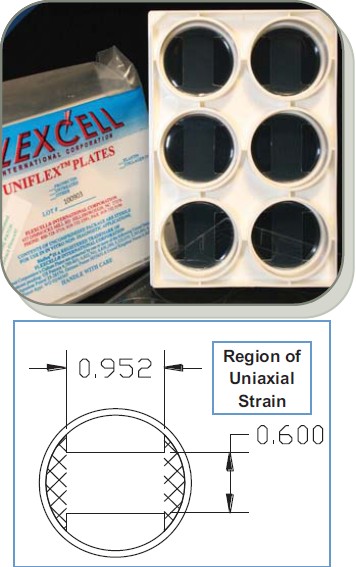

2、UniFlex™单向应力细胞培养板(UniFlex™Culture Plates)

| 编号产品 | 产品名称 | |

| UF-4001U-Case(每箱40块) | UF-4001U-Each(每块) | UniFlex Culture Plate-Untreated(6孔表面未处理的BioFLEX®双向应力细胞培养板) |

| UF-4001A-Case(每箱40块) | UF-4001A-Each(每块) | UniFlex Culture Plate-Amino(6孔氨基UniFlex™单向应力细胞培养板) |

| UF-4001C-Case(每箱40块) | UF-4001C-Each(每块) | UniFlex Culture Plate-Collagen Type I(6孔胶原I 型UniFlex™单向应力细胞培养板) |

| UF-4001C(IV)-Case(每箱40块) | UF-4001C(IV)-Each(每块) | UniFlex Culture Plate-Collagen Type IV(6孔胶原IV型UniFlex™单向应力细胞培养板) |

| UF-4001E-Case(每箱40块) | UF-4001E-Each(每块) | UniFlex Culture Plate-Elastin (6孔弹力UniFlex™单向应力细胞培养板) |

| UF-4001P-Case(每箱40块) | UF-4001P-Each(每块) | UniFlex Culture Plate-ProNectin (6孔ProNectin UniFlex™单向应力细胞培养板) |

| UF-4001L-Case(每箱40块) | UF-4001L-Each(每块) | UniFlex Culture Plate-Laminin (6孔层粘连蛋白UniFlex™单向应力细胞培养板) |

3、HT BIOFLEX®CULTURE PLATES(高通量BIOFLEX®培养板培养板) | ||

| 白色板 | ||

编号产品 | 产品名称 | |

| HTPW-3001U-Case(每箱40块) | HTPW-3001U-Each(每块) | White HT BioFlex Culture Plate-Untreated(白色24孔高通量表面未处理培养板) |

| HTPW-3001A-Case(每箱40块) | HTPW-3001A-Each(每块) | White HT BioFlex Culture Plate-Amino(白色24孔高通量氨基培养板) |

| HTPW-3001C-Case(每箱40块) | HTPW-3001C-Each(每块) | White HT BioFlex Culture Plate-Collagen Type I(白色24孔高通量胶原I型培养板) |

| HTPW-3001C(IV)-Case(每箱40块) | HTPW-3001C(IV)-Each(每块) | White HT BioFlex Culture Plate-Collagen Type IV(白色24孔高通量胶原IV型培养板) |

| HTPW-3001E-Case(每箱40块) | HTPW-3001E-Each(每块) | White HT BioFlex Culture Plate-Elastin(白色24孔高通量弹力培养板) |

| HTPW-3001P-Case(每箱40块) | HTPW-3001P-Each(每块) | White HT BioFlex Culture Plate-ProNectin(白色24孔高通量ProNectin 培养板) |

| HTPW-3001L-Case(每箱40块) | HTPW-3001L-Each(每块) | White HT BioFlex Culture Plate-Laminin(白色24孔高通量层粘连蛋白培养板) |

| 黑色板 | ||

| HTPB-3001U-Case(每箱40块) | HTPB-3001U-Each(每块) | Black HT BioFlex Culture Plate-Untreated(黑色24孔高通量表面未处理培养板) |

| HTPB-3001A-Case(每箱40块) | HTPB-3001A-Each(每块) | Black HT BioFlex Culture Plate-Amino(黑色24孔高通量氨基培养板) |

| HTPB-3001C-Case(每箱40块) | HTPB-3001C-Each(每块) | Black HT BioFlex Culture Plate-Collagen Type I(黑色24孔高通量胶原I培养板) |

| HTPB-3001C(IV)-Case(每箱40块) | HTPB-3001C(IV)-Each(每块) | Black HT BioFlex Culture Plate-Collagen Type IV(黑色24孔高通量胶原IV培养板) |

| HTPB-3001E-Case(每箱40块) | HTPB-3001E-Each(每块) | Black HT BioFlex Culture Plate-Elastin(黑色24孔高通量弹力培养板) |

| HTPB-3001P-Case(每箱40块) | HTPB-3001P-Each(每块) | Black HT BioFlex Culture Plate-ProNectin(黑色24孔高通量ProNectin培养板) |

| HTPB-3001L-Case(每箱40块) | HTPB-3001L-Each(每块) | Black HT BioFlex Culture Plate-Laminin(黑色24孔高通量层粘连蛋白培养板) |

| |||

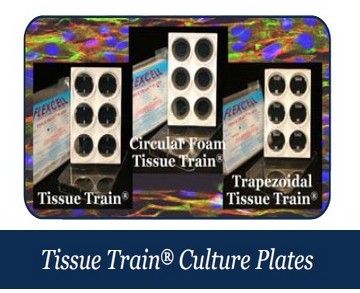

| CIRCULAR FOAM TISSUE TRAIN CULTURE PLATES (圆形三维细胞组织培养板采用弹性底部,可用来制备三维基质蛋白细胞培养物,并提供双轴向拉力,不需要生物胶槽(Trough Loader)) | |||

| 编号产品 | 产品名称 | ||

| TTCF-4001U-Case | TTCF-4001U-Each | Circular Foam Culture Plate-Untreated | |

| TTCF-4001A-Case | TTCF-4001A-Each | Circular Foam Culture Plate-Amino | |

| TTCF-4001C-Case | TTCF-4001C-Each | Circular Foam Culture Plate-Collagen Type I | |

| TTCF-4001C(IV)-Case | TTCF-4001C(IV)-Each | Circular Foam Culture Plate-Collagen Type IV | |

| TTCF-4001E-Case | TTCF-4001E-Each | Circular Foam Culture Plate-Elastin | |

| TTCF-4001P-Case | TTCF-4001P-Each | Circular Foam Culture Plate-ProNectin | |

| TTCF-4001L-Case | TTCF-4001L-Each | Circular Foam Culture Plate-Laminin | |

| TISSUE TRAIN CULTURE PLATES (三维细胞组织培养板采用弹性底部,可用来制备三维基质蛋白细胞培养物,并提供单轴向拉力。) | |||

| 编号产品 | 产品名称 | ||

| Foruse with Standard Trough Loaders (与线形生物胶槽配套使用) | |||

| TT-4001U-Case | TT-4001U-Each | Tissue Train Culture Plate-Untreated | |

| TT-4001A-Case | TT-4001A-Each | Tissue Train Culture Plate-Amino | |

| TT-4001C-Case | TT-4001C-Each | Tissue Train Culture Plate-Collagen Type I | |

| TT-4001C(IV)-Case | TT-4001C(IV)-Each | Tissue Train Culture Plate-Collagen Type IV | |

| TT-4001E-Case | TT-4001E-Each | Tissue Train Culture Plate-Elastin | |

| TT-4001P-Case | TT-4001P-Each | Tissue Train Culture Plate-ProNectin | |

| TT-4001L-Case | TT-4001L-Each | Tissue Train Culture Plate-Laminin | |

| Foruse with Trapezoidal Trough Loaders (与梯形生物胶槽配套使用) | |||

| 编号产品 | 产品名称 | ||

| TTTP-4001U-Case | TTTP-4001U-Each | Trapezoidal TT Culture Plate-Untreated | |

| TTTP-4001A-Case | TTTP-4001A-Each | Trapezoidal TT Culture Plate-Amino | |

| TTTP-4001C-Case | TTTP-4001C-Each | Trapezoidal TT Culture Plate-Collagen Type I | |

| TTTP-4001C(IV)-Case | TTTP-4001C(IV)-Each | Trapezoidal TT Culture Plate-Collagen Type IV | |

| TTTP-4001E-Case | TTTP-4001E-Each | Trapezoidal TT Culture Plate-Elastin | |

| TTTP-4001P-Case | TTTP-4001P-Each | Trapezoidal TT Culture Plate-ProNectin | |

| TTTP-4001L-Case | TTTP-4001L-Each | Trapezoidal TT Culture Plate-Laminin | |

| ||

| CIRCULAR FOAM TISSUE TRAIN CULTURE PLATES (圆形三维细胞组织培养板采用弹性底部,可用来制备三维基质蛋白细胞培养物,并提供双轴向拉力,不需要生物胶槽(Trough Loader)) | ||

| 编号产品 | 产品名称 | |

| TTCF-4001U-Case | TTCF-4001U-Each | Circular Foam Culture Plate-Untreated |

| BioFlex® Culture Plate Catalog Page   | Product Information | Brochure | Application Page | Product Information | Brochure | Application Page |  Find Distributor Search FAQs |

Flexible-bottomed culture plate that works with the Flexcell® FX-5000™ Tension Systemto provide a mechanical load regimen to cells in monolayer (see Fig. 1 below).

Applications of BioFlex® Culture Plates

Relevant Tech Reports & Other Information

|

The History of Flexcell®

In 1978, Albert J. Banes, Ph.D., an Assistant Professor in the Surgery Department at the University of North Carolina at Chapel Hill, received his first small grant for devising a method to apply regulated strain to cultured cells. He built prototypes of the current Flexcell® Tension System in the shop using only a timer, a simple solenoid valve to control pressure in on/off modes, and a needle valve to regulate the magnitude of the pressure. He built a baseplate with vacuum channels in Plexiglas and used natural gum rubber as the seal between the culture plate bottom and the vacuum chamber. Dr. Banes polymerized his own rubber membranes from medical grade Dow silastic components. A cast material that eventually proved satisfactory for the membrane in a 6-well, 35 mm diameter culture plate that had the well bottoms drilled out to receive the cast membranes. A Commodore Vic 20 was the first commercial microprocessor used to control the valves. The software program and a controller board were designed by Dr. Banes and a well grounded electronics engineer, Olivier Monbureau. A Commodore 64 was the next generation computer used, followed by a Tandy computer, then IBM clones. Today, Flexcell® develops its own software and builds custom computers and controller boards and assembles them at its plant in Burlington, NC.

Dr. Banes' inlectual property was awarded the first patent in the field of Cytomechanics. He believed that this technology could become important scientifically as well as medically if a market driver could be found. In his first patent describing the technology, he included the thought that cyclically stretching cells and tissues could lead to adaptation of cells to a mechanically active environment such as dermal fibroblasts cultured in vitro in a skin construct. Along with his father in Pennsylvania, G.B. Banes, J.D., they created Flexcell® Inc. The company's mission was to commercialize the technology to make it available to all scientists as well as find medically relevant uses. His first full publication (Journal of Cell Science, 1985) in the area demonstrated the utility of the system and that cyclic strain altered the expression of cytoplasmic filament proteins such as actin and tubulin in tendon cells.

Continued development of the technologies behind the Flexcell® Tension and Compression Systems has taken much of Dr. Banes' time. Dr. Banes became the first university professor to be permitted to retain his academic professorship and be president of a company (Flexcell® International Corporation) by a decision of the Committee on Industrial Faculty Relations at the University of North Carolina at Chapel Hill.

Dr. Banes holds three patents on the basic cell stretching technology and several more on other technologies including a DNA transfection technique using flexation of cells and a spill resistant culture plate called the SpillGuard® culture plate. He continues to develop new products for cell culture and cell stretching as well as submit patents assigned to Flexcell® International Corporation.

Our Mission