Leybold/德国莱宝 品牌

其他厂商性质

苏州市所在地

莱宝氦质谱L300i MODUL PHOENIX检漏仪租赁

¥150000

PHOENIX Magno and Magno dry 4.0检漏仪

¥280000

莱宝PHOENIX Vario PHOENIX4.0氦质谱检漏仪

¥250000

手持式数字莱宝真空计

¥8500

莱宝潘宁真空计

¥8800

莱宝真空计

¥5500

莱宝电离真空计

¥15000

莱宝潘宁真空计PTR225N PTR90N

¥14500

莱宝皮拉尼真空计TTR91N TTR96N

¥5500

莱宝电容薄膜真空计CTR100N,CTR101N

¥12000

莱宝线性真空计DU200、DU201、 DU2000维修

¥8500

莱宝DI-传感器 线性真空计DI2000校准保养

¥8000

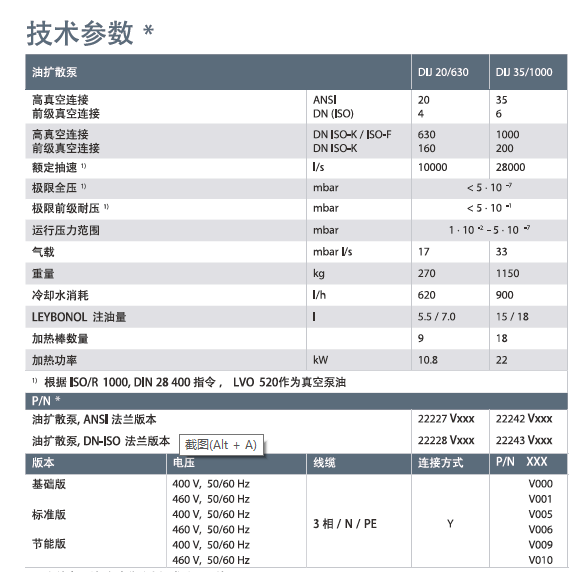

DIJ产品优势1、能耗低,加热块创新的加热原理,加热棒与泵油家畜面积更大,加快热能的传导,加热区域高效隔热,减少能量损耗。+延长加热棒及泵油使用寿命+法兰连接的加热棒,更换简单2、高压强下抽速大,耐气载能力强五级喷嘴系统设计,在10-2-10-3mbar下抽空性能更佳。3、新型挡板设计,返油少+进气口冷帽挡板确保小油蒸汽反流+新设计的前级真空挡板*的减少油气损耗4、安装适配性高

德国莱宝油扩散真空泵泵 DIJ 20 维修保养

DIJ产品优势

1、能耗低,加热块

创新的加热原理,加热棒与泵油家畜面积更大,加快热能的传导,加热区域高效隔热,减少能量损耗。

+延长加热棒及泵油使用寿命

+法兰连接的加热棒,更换简单

2、高压强下抽速大,耐气载能力强

五级喷嘴系统设计,在10-2-10-3mbar下抽空性能更佳。

3、新型挡板设计,返油少

+进气口冷帽挡板确保小油蒸汽反流

+新设计的前级真空挡板*的减少油气损耗

4、安装适配性高

为客户提供更多的法兰种类选择

+ANSI/INCH法兰带O圈

+ISO-F或ISO-K法兰带中心环

5、多种电气连接选择

满足更多的客户需求

+三种不同连接方式

-基础班:带工业标准接头适用于OEM

-标准版:带短路保护电器盒

-节能版:带配电箱和节能控制单元

苏州昆山太仓无锡上海张家港德国莱宝油扩散真空泵泵 DIJ 20 维修保养

吴江常熟镇江常州扬州泰州南通德国莱宝油扩散真空泵泵 DIJ 20 维修保养

南京启东海门如皋海门海安如东德国莱宝油扩散真空泵泵 DIJ 20 维修保养

宿迁徐州合肥芜湖杭州湖州温州德国莱宝油扩散真空泵泵 DIJ 20 维修保养

台州衢州绍兴金华宁波余姚福州德国莱宝油扩散真空泵泵 DIJ 20 维修保养

厦门泉州深圳广州珠海广州惠州德国莱宝油扩散真空泵泵 DIJ 20 维修保养

通州桂林南宁南昌赣州武汉成都德国莱宝油扩散真空泵泵 DIJ 20 维修保养

重庆荆州太原兰州乌鲁木齐石家庄德国莱宝油扩散真空泵泵 DIJ 20 维修保养

天津长春吉林济南青岛威海德州德国莱宝油扩散真空泵泵 DIJ 20 维修保养

连云港昆明九江安庆德国莱宝油扩散真空泵泵 DIJ 20 维修保养

经典应用

真空镀膜

冶金

真空炉

真空干燥

研发

德国莱宝油扩散真空泵泵 DIJ 20 维修保养

DIJ油扩散泵优点:维修间隔长,无磨损,安全标准高。

在大于10-3mbar下稳定的高气载

前级耐压高

抽速大

安全节能

电气元件复合CE标准

无移动元件磨损

操作简单

维护简便,替换加热棒简单快捷

可用附件种类多

DIJ油扩散泵优点:维修间隔长,无磨损,安全标准高。

在大于10-3mbar下稳定的高气载

前级耐压高

抽速大

安全节能

电气元件复合CE标准

无移动元件磨损

操作简单

维护简便,替换加热棒简单快捷

可用附件种类多

经典应用

真空镀膜

冶金

真空炉

真空干燥

研发

■ Most innovative heating concept utilizing newly developed heater cartridges with large heat exchange surface for an optimized energy transfer into the oil. Effective temperature monitoring protects the system against overheating. The insulated heater area ensures minimum energy losses.

+ Minimum stress and longest lifetime for heaters and oil

+ Highest uptime

+ Flanged heaters, easy to exchange

■ Choice of flange variants for improved connectivity

+ ANSI / Inch flanges (with O-ring)

+ ISO-F or ISO-K flanges (with centering ring)

■ Unique baffle design + Proven cold cap baffle at the inlet to minimize oil backstreaming

+ Innovative, new foreline baffle for reduced oil losses

■ Various electrical connection opportunities to meet customers requirements

+ Basic – simplified OEM connection with male plug

+ Standard – with circuit breaker box

+ ECO, with switchbox and energy control unit

■ Five stage system design provides excellent performance data

+ Four diffusion pump stages for highest suction speed at low pressures and lowest final pressure

+ One ejector stage for high forevacuum stability and stable throughput at pressures >10-3 mbar

■ Vacuum coating

■ Metallurgy

■ Vacuum furnaces

■ Vacuum drying

■ Research and development

Prolonged maintenance intervals, non-wearing, high safety standard.

■ High and stable throughput at pressures >10-3 mbar

■ High forevacuum tolerance

■ High pumping speed

■ Safe and economical

■ CE compliant electronics supplied

■ No wear caused by moving parts

■ Simple to operate

■ Maintenance friendly design for rapid and simple replacement of heating elements

■ Wide range of accessories available

■ Innovative ECO Energy control unit (ROI

Energy savings up to 30% without power loss

Oil diffusion pumps require a certain minimum oil temperature for operation. Commonly, 100% of the installed heating power is constantly utilized. The innovative Leybold power efficiency control unit for diffusion pumps cuts power consumption by up to 30% since the supplied power is significantly reduced after the pump has attained its operating temperature. Further savings result from the utilization of the standby mode at a reduced temperature.

■ Cost reductions through energy-savings (up to 30%)

■ Increased service life of oil and heating cartridges

■ Excellent operating convenience and simple use

■ Fast ROI (< 2 years)

■ Simple, visual monitoring of the parameters

■ PLC driven

■ USB Interface and Ethernet