Western's advanced Bridging Pit Gauge System® and our new Jr. Bridging Pit Gauge® take over, where the capabilities of our standard Pit Gauges fall short, for evaluating large areas of Weightloss Corrosion. These Bridging Bar type Pit Gauges can also be used to measure Dents and Buckles on Pipelines, Shell Settlement on Storage Tanks, etc. These various forms of Bridging Bars can utilize any of our exclusive Dial Indicators (Imperial, Metric, or Digital), with any of our Custom Engineered Contact Points.

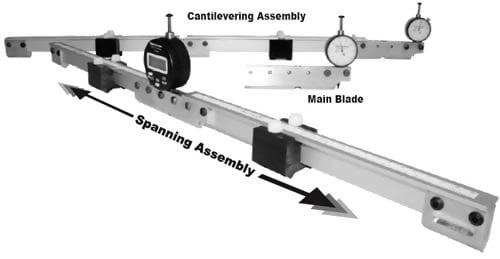

There are several important features to a Segmented Bridge, where various elements (Blades and Tees) are assembled to form a Bridging Bar. Firstly, they can be assembled to follow the contour of a slightly irregular surface. This contouring feature is important for Pipeline, Storage Tank, and Pressure Vessel inspections, where 'hills and valleys' always exist. Secondly, the models listed below are of a given length, however extra elements can be added to increase their overall length. As illustrated, these units can be assembled in Spanning or Cantilevering configurations, and finally, the Main Blade can be used individually for isolated or cone type Pitting.

基本桥接测坑仪Bridging Pit Gauge® System

The Bridging Pit Gauge® System allows the Corrosion Inspector to Span over or Cantilever into Large Areas of Weight Loss Corrosion, to obtain accurate and consistent measurements, or cross sections, of Pit Depth. As conditions dictate, the operator can simply use the Main Blade or can assemble the Bridging Pit Gauge® up to an overall length of 28½" (725mm). The contact Surfaces (Blades) of the Bridging Pit Gauge® are fitted with an exclusive Knife Edge, so they can be used on Flat, ID (Convex), and OD (Concave) Surfaces, where a flat or notched contact surface can introduces error on Convex Surfaces. Like our Standard Pit Gauges, the Knife Edge gives the operator a clear view of the contact point, and the area being inspected. With the addition of the optional Magnetic Hold Downs, the operator uses their width to quickly align the Bridging Pit Gauge® System to a curved surface. This leaves his hands free to scan through very large areas of weight loss corrosion. This holds true when the Bridge Elements have been assembled with a slight contour on an irregular surface. | NAME | PART NUMBER | DESCRIPTION |

|---|

Bridging

Pit Gauge | N88-9 | Main Blade, Imperial Dial Indicator, Connector Blade, 2-Extender Tees, End Blade, Slider Blade, Hardware, Extra Contact Point, and Carrying Case. | | Main Blade | N88-9-1 | Center and End Dial Indicator Mounting Positions, Cutaway Nose for next to welds. 5.5" (144mm) long. | | Connector Blade | N88-9-2 | Joins Tee Sections to increase length. 3.5" (90mm) long. | | End Blade | N88-9-3 | Mounts on end of Tee for extra contact. 1.5" (38mm) long. | | Slider Blade | N88-9-4 | Extra Point of Contact and doubles as an End Blade in Spanning Configuration. 1.5" (38mm) long. | | Extender Tee | N88-9-5 | Extends effective length of all models. 12" (305mm) long (Longer Tees are optional). | Magnetic

Hold Downs | N88-9-6 | 1 required for each Tee Section used. 15/8" (41mm) long. | | Fastener Kit | N88-9-7 | Fasteners, Al |

基本桥接测坑仪Downloads

| N88-9B Basic Bridging Pit Gauge Instruction Manual |

Buy Now

|