SH/双环仪表 品牌

生产厂家厂商性质

上海市所在地

A41Y不锈钢安全阀产品用途

不锈钢安全阀A41Y整体材质选用优质不锈钢铸造而成,采用全封闭阀盖和阀帽结构,安全阀开启排放时,介质不会向外界泄漏,而全部通过排泄管排掉,又可防止灰尘等杂质进入阀内,适用于温度不高于200°C的腐蚀性气体和需要大排量的液体介质。上海申弘阀门有限公司是国内生产安全阀的主导厂,厂内建有远东*的安全阀测试中心,国产*台安全阀就是我厂诞生的,二十多年来,申弘牌安全阀的品种已发展到百余个系列,千余个规格,产品广泛应用于锅炉、石化、电站以及国防工业。并为国内*座核电站秦山核电站研制成功了*批核级安全阀。

安全阀是受压设备、容器或管路上的*超压保护装置。当设备压力升高达到预定值时,安全阀自动开启,继而全量排放,防止设备压力继续升高;当压力降低到规定值时,安全阀及时自动关闭。申弘牌安全阀是选用者为保护工程设备安全运行的的,zui科学的明智选择。所谓安全阀广义上讲包括泄放阀,从管理规则上看,直接安装在蒸汽锅炉或一类压力容器上,其必要条件是必须得到技术监督部门认可的阀门,狭义上称之为安全阀,其他一般称之为泄放阀。安全阀与泄放阀在结构和性能上很相似,二者都是在超过开启压力时自动排放内部的介质,以保证生产装置的安全。由干存在这种本质上类似性,人们在使用时,往往将二者混同,另外,有些生产装置在规则上也规定选用哪种均可。因此,二者的不同之处往往被忽视。从而也就出现了许多间题。如果要将二者作出比较明确的定义,则可按照《ASME锅炉及压力容器规范》*篇中所阐述的定义来理解:

A41Y不锈钢安全阀产品特点

执行标准

设计规范:GB/T 12243

结构长度:GB/T 12221

法兰连接:JB/T 79

试验与检验:GB/T 12242

产品标识:GB/T 12220

供货规范:JB/T 7928

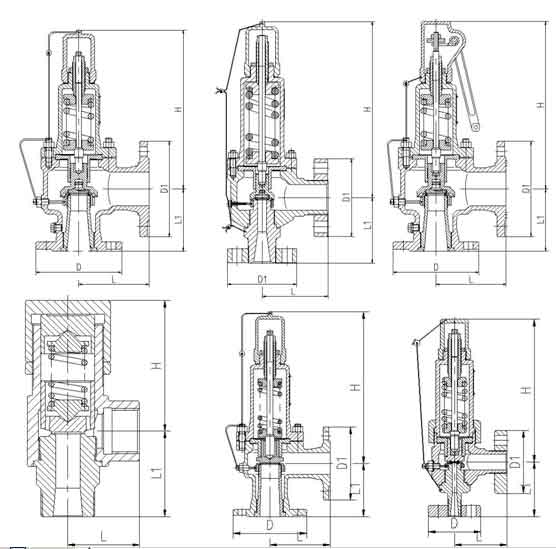

A41Y不锈钢安全阀主要连接尺寸:

型 号 | 公称 | 主要结构尺寸(mm) | 阀体 材料 | 简要性能 | 备注 | ||||||

通径 DN(mm) | 压力 PN(Mpa) | D | D1 | L | L1 | H | 适用温度 ℃ | 适用介质 | |||

A21W-16P | 15 | 1.6 |

|

| 35 | 60 | 64 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 20 | " |

|

| 40 | 68 | 68 | " | " | " |

|

" | 25 | " |

|

| 50 | 78 | 105 | " | " | " |

|

A21W-25P | 15 | 2.5 |

|

| 35 | 60 | 64 | 1Cr18Ni9Ti | " | " |

|

" | 20 | " |

|

| 40 | 68 | 68 | " | " | " |

|

" | 25 | " |

|

| 50 | 78 | 105 | " | " | " |

|

A21W-40P | 15 | 4.0 |

|

| 35 | 60 | 64 | " | " | " |

|

" | 20 | " |

|

| 40 | 68 | 68 | " | " | " |

|

" | 25 | " |

|

| 50 | 78 | 105 | " | " | " |

|

A41Y-16P | 32 | 1.6 | 135 | 135 | 115 | 100 | 266 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 145 | 120 | 105 | 318 | " | " | " |

|

" | 50 | " | 160 | 160 | 130 | 115 | 350 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 385 | " | " | " |

|

" | 100 | " | 215 | 215 | 170 | 160 | 525 | " | " | " |

|

" | 150 | " |

|

|

|

|

| " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A41Y-25P | 32 | 2.5 | 135 | 135 | 115 | 100 | 266 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 145 | 120 | 105 | 318 | " | " | " |

|

" | 50 | " | 160 | 160 | 130 | 115 | 340 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 565 | " | " | " |

|

" | 100 | " | 230 | 215 | 170 | 160 | 580 | " | " | " |

|

A41Y-40P | 32 | 4.0 | 135 | 135 | 115 | 100 | 266 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 145 | 120 | 105 | 318 | " | " | " |

|

" | 50 | " | 160 | 160 | 130 | 115 | 340 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 565 | " | " | " |

|

" | 100 | " |

|

|

|

|

| " | " | " |

|

A41Y-16R | 32 | 1.6 | 135 | 135 | 115 | 100 | 260 | OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 145 | 120 | 105 | 318 | " | " | " |

|

" | 50 | " | 160 | 160 | 130 | 115 | 350 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 385 | " | " | " |

|

" | 100 | " | 215 | 215 | 170 | 160 | 525 | " | " | " |

|

" | 150 | " |

|

|

|

|

| " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A41Y-25R | 32 | 2.5 | 135 | 135 | 115 | 100 | 266 | OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 145 | 120 | 105 | 318 | " | " | " |

|

" | 50 | " | 160 | 160 | 130 | 115 | 350 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 570 | " | " | " |

|

" | 100 | " | 230 | 215 | 170 | 160 | 580 | " | " | " |

|

" | 150 | " |

|

|

|

|

|

|

|

|

|

A41Y-40R | 32 | 4.0 | 135 | 135 | 115 | 100 | 266 | OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 150 | 150 | 120 | 110 | 320 | " | " | " |

|

" | 50 | " | 165 | 165 | 135 | 120 | 340 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 195 | 160 | 135 | 570 | " | " | " |

|

" | 100 | " |

|

|

|

|

| " | " | " |

|

" | 150 | " |

|

|

|

|

| " | " | " |

|

SA41H-16P | 25 | 1.6 | 115 | 45 | 55 | 85 | 200 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

SA41H-25P | 25 | 2.5 | 115 | 45 | 55 | 85 | 200 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

SA41H-40P | 25 | 4.0 | 115 | 45 | 55 | 85 | 200 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

SA41H-64P | 25 | 6.4 | 135 | 45 | 55 | 85 | 200 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

SA41Y-160P | 15 | 16.0 | 95 | 115 | 95 | 100 | 238 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 20 | " |

|

|

|

|

|

|

|

|

|

" | 25 | " |

|

|

|

|

|

|

|

|

|

" | 32 | " | 115 | 165 | 165 | 135 | 310 | " | " | " |

|

SA41Y-320P | 15 | 32.0 | 105 | 115 | 95 | 100 | 238 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 20 | " | 110 | 115 | 95 | 100 | 238 | " | " | " |

|

" | 25 | " |

|

|

|

|

| " | " | " |

|

" | 32 | " | 135 | 165 | 130 | 135 | 334 | " | " | " |

|

SA41Y-500P | 15 | 50.0 | 105 | 115 | 95 | 100 | 222 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

A42Y-16P | 25 | 1.6 |

|

|

|

| 230 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 32 | " | 135 | 145 | 115 | 100 | 285 | " | " | " |

|

" | 40 | " | 150 | 160 | 120 | 110 | 278 | " | " | " |

|

" | 50 | " | 165 | 180 | 135 | 120 | 323 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 200 | 215 | 170 | 135 | 478 | " | " | " |

|

" | 100 | " | 220 | 245 | 205 | 160 | 590 | " | " | " |

|

" | 150 | " | 280 | 310 | 255 | 230 | 650 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A42Y-40P | 32 | 4.0 | 140 | 150 | 115 | 100 | 285 | 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 160 | 130 | 115 | 278 | " | " | " |

|

" | 50 | " | 160 | 180 | 145 | 130 | 332 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 215 | 170 | 150 | 478 | " | " | " |

|

" | 100 | " | 230 | 245 | 205 | 185 | 590 | " | " | " |

|

" | 150 | " | 300 | 310 | 255 | 230 | 650 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A42Y-64P | 32 | 6.4 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 165 | 160 | 130 | 120 | 305 | " | " | " |

|

" | 50 | " | 175 | 180 | 155 | 130 | 462 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 210 | 230 | 175 | 160 | 582 | " | " | " |

|

" | 100 | " | 250 | 270 | 195 | 195 | 600 | " | " | " |

|

A42Y-100P | 32 | 10.0 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " |

|

|

|

|

| " | " | " |

|

" | 50 | " |

|

|

|

|

| " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " |

|

|

|

|

| " | " | " |

|

" | 100 | " |

|

|

|

|

| " | " | " |

|

A42Y-16R | 25 | 1.6 |

|

|

|

|

| OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 32 | " | 135 | 145 | 115 | 100 | 265 | " | " | " |

|

" | 40 | " | 150 | 160 | 120 | 110 | 278 | " | " | " |

|

" | 50 | " | 165 | 180 | 135 | 120 | 332 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 200 | 215 | 170 | 135 | 478 | " | " | " |

|

" | 100 | " | 220 | 245 | 205 | 160 | 590 | " | " | " |

|

" | 150 | " | 280 | 310 | 255 | 230 | 650 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A42Y-40R | 32 | 4.0 | 140 | 150 | 115 | 100 | 260 | OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 160 | 130 | 120 | 278 | " | " | " |

|

" | 50 | " | 160 | 180 | 145 | 130 | 332 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 195 | 215 | 170 | 150 | 478 | " | " | " |

|

" | 100 | " | 230 | 245 | 205 | 185 | 590 | " | " | " |

|

" | 150 | " | 300 | 310 | 255 | 230 | 650 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A42Y-64R | 32 | 6.4 |

|

|

|

|

| OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 165 | 160 | 130 | 120 | 308 | " | " | " |

|

" | 50 | " | 175 | 180 | 155 | 130 | 464 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 210 | 230 | 175 | 160 | 582 | " | " | " |

|

" | 100 | " | 250 | 270 | 195 | 195 | 600 | " | " | " |

|

A42Y-100R | 32 | 10.0 |

|

|

|

|

| OCr18Ni12Mo2Ti | ≤200 | 醋酸类 |

|

" | 40 | " |

|

|

|

|

| " | " | " |

|

" | 50 | " |

|

|

|

|

| " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " |

|

|

|

|

| " | " | " |

|

" | 100 | " |

|

|

|

|

| " | " | " |

|

A44Y-16P | 32 | 1.6 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 150 | 165 | 120 | 110 | 314 | " | " | " |

|

" | 50 | " | 165 | 185 | 135 | 120 | 375 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 200 | 220 | 170 | 135 | 538 | " | " | " |

|

" | 100 | " | 215 | 245 | 205 | 185 | 655 | " | " | " |

|

" | 150 | " | 280 | 310 | 255 | 230 | 740 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A44Y-40P | 32 | 4.0 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " | 145 | 165 | 130 | 120 | 314 | " | " | " |

|

" | 50 | " | 160 | 180 | 145 | 130 | 376 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 190 | 215 | 170 | 150 | 538 | " | " | " |

|

" | 100 | " | 250 | 245 | 205 | 185 | 655 | " | " | " |

|

" | 150 | " | 300 | 310 | 255 | 230 | 740 | " | " | " |

|

" | 200 | " |

|

|

|

|

| " | " | " |

|

A44Y-64P | 32 | 6.4 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " |

|

|

|

|

| " | " | " |

|

" | 50 | " | 175 | 180 | 155 | 130 | 520 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 210 | 230 | 185 | 160 | 810 | " | " | " |

|

" | 100 | " | 250 | 270 | 195 | 195 | 890 | " | " | " |

|

A44Y-100P | 32 | 10.0 |

|

|

|

|

| 1Cr18Ni9Ti | ≤200 | 醋酸类 |

|

" | 40 | " |

|

|

|

|

| " | " | " |

|

" | 50 | " | 195 | 180 | 155 | 130 | 520 | " | " | " |

|

" | 65 | " |

|

|

|

|

| " | " | " |

|

" | 80 | " | 230 | 230 | 175 | 160 | 815 | " | " | " |

|

" | 100 | " | 265 | 270 | 220 | 210 | 680 | " |

A41Y不锈钢安全阀各种工况下使用寿命安全阀比较合理:

(l)热水锅炉一般用不封闭带扳手微启式安全阀。

(2)蒸汽锅炉或蒸汽管道一般用不封闭带扳手全启式安全阀。

(3)水等液体不可压缩介质一般用封闭微启式安全阀,或用安全泄放阀。

(4)高压给水一般用封闭全启式安全阀,如高压给水加热器、换热器等。

(5)气体等可压缩性介质一般用封闭全启式安全阀,如储气罐、气体管道等。

(6)E级蒸汽锅炉一般用静重式安全阀。

(7)大口径,大排量及高压系统一般用脉冲式安全阀,如减温减压装置、电站锅炉等,如图8所示。

(8)运送液化气的火车槽车、汽车槽车、贮罐等一般用内装式安全阀,如图4所示。

(9)油罐顶部一般用液压安全阀,需与呼吸阀配合使用。

(10)井下排水或天然气管道一般用先导式安全阀,如图6所示。

(11)液化石油气站罐泵出口的液相回流管道上一般用安全回流阀。

(12)负压或操作过程中可能会产生负压的系统一般用真空负压安全阀。

(13)背压波动较大和有毒易燃的容器或管路系统一般用波纹管安全阀。

订货须知:

一、①产品名称与型号②口径③是否带附件以便我们的为您正确选型④使用压力⑤使用介质的温度。

二、若已经由设计单位选定公司的安全阀型号,请型号直接向我司销售部订购。

三、当使用的场合非常重要或环境比较复杂时,请您尽量提供设计图纸和详细参数,由我们的阀门公司专家为您审核把关。如有疑问:请:我们一定会尽心尽力为您提供优质的服务。提供zui全面、专业的“阀门系统解决方案”,也十分愿意帮助用户解决生产中所遇到的难题。